Any project brings some new challenges. We believe this should be carefully evaluated in order to have a successful outcome. our approach regarding the technical feasibility is as below:

Thank you for reading this post, don't forget to subscribe!- OTOM will evaluate the feasibility of the project per the capability of the software and provide feedback within (1-3 weeks).

- In case of a successful evaluation, OTOM prepares a quotation including all estimated expenses such as labor cost, working hours, hardware equipment deprecation, and travel cost (including 1-2 days visit at the production site for data acquisition).

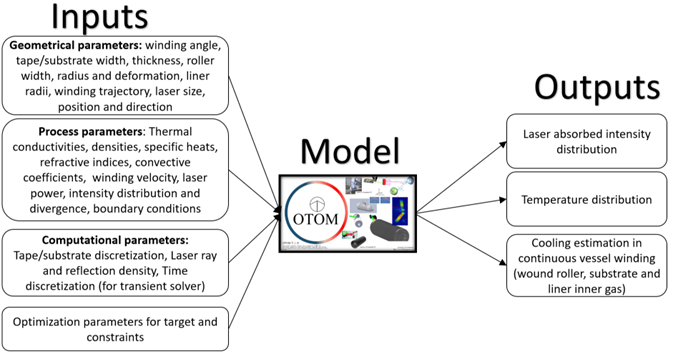

The data should be gathered for further analysis. The data structure in OTOM AFP software consists of 2 main channels, inputs, and outputs. They are classified in order to give the user a structural way to analyze the results.

Data structure

The model inputs are designed and classified based on the automated fiber placement process and influencing parameters. All the parameters that are provided as input for OTOM can be divided into Geometrical Parameters, Process Parameters, and Computational Parameters.

OTOM Engineering service

A. Model inputs to:

i. Geometrical parameters

ii. Process parameters

iii. Computational parameters

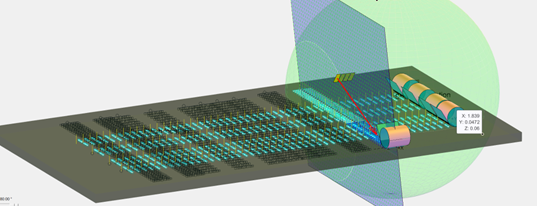

These parameters help to build the simulation setup and corresponding physical properties. An exemplary kinematic determination case is shown below.

The OTOM model outputs are general numerical values represented as numbers, graphs, contour images, and animations. They are intended to give the user an easy and fast understanding of real-world AFP outcomes via digital content. A high-level representation of OTOM models is shown below.

B. Model output results from:

i. Kinematics simulation

ii. Optical simulation

iii. Thermal simulation

iv. Optimization