We developed a technology to help the composite industry design and make products easier and faster.

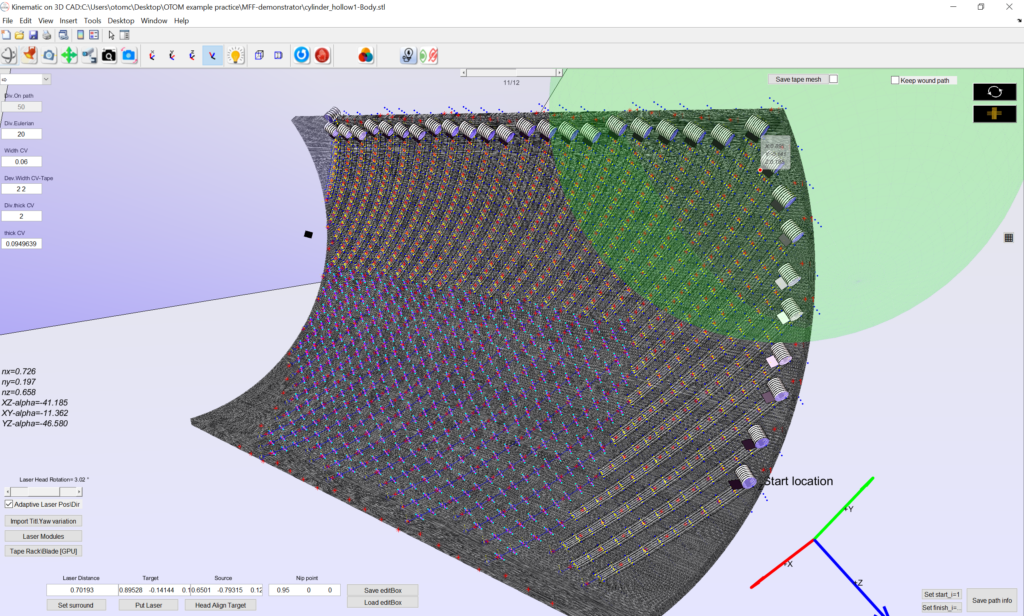

Proudly, we are offering the First Process Simulation software for Automated Fiber Placement (AFP) technology.

AFP Software Tutorials?

…

Read about our last month visit to Fraunhofer IGCV.

Kick off new R&D project

…

TU-Delft and other

industrial partners

What is AFP?

Automated Fiber Placement (AFP) is an additive manufacturing technique specifically designed for the production of lightweight composites, such as Continuous Glass/Carbon fiber-reinforced (FRP). AFP enables a fully automated single-step manufacturing process where FRP prepreg tapes are consolidated “in situ.” This approach not only reduces production costs significantly but also eliminates the need for post-consolidation or curing steps. The efficiency of AFP lies in its ability to seamlessly consolidate and shape FRP materials during the manufacturing process, streamlining the production of lightweight composite components.

OTOMcomposite assists customers in predicting and designing necessary process parameters based on factors such as heat input, tooling geometry, and process parameters. This capability is particularly crucial in the early stages of product development, as it contributes to cost reduction, accelerates project timelines, and enhances final product performance.

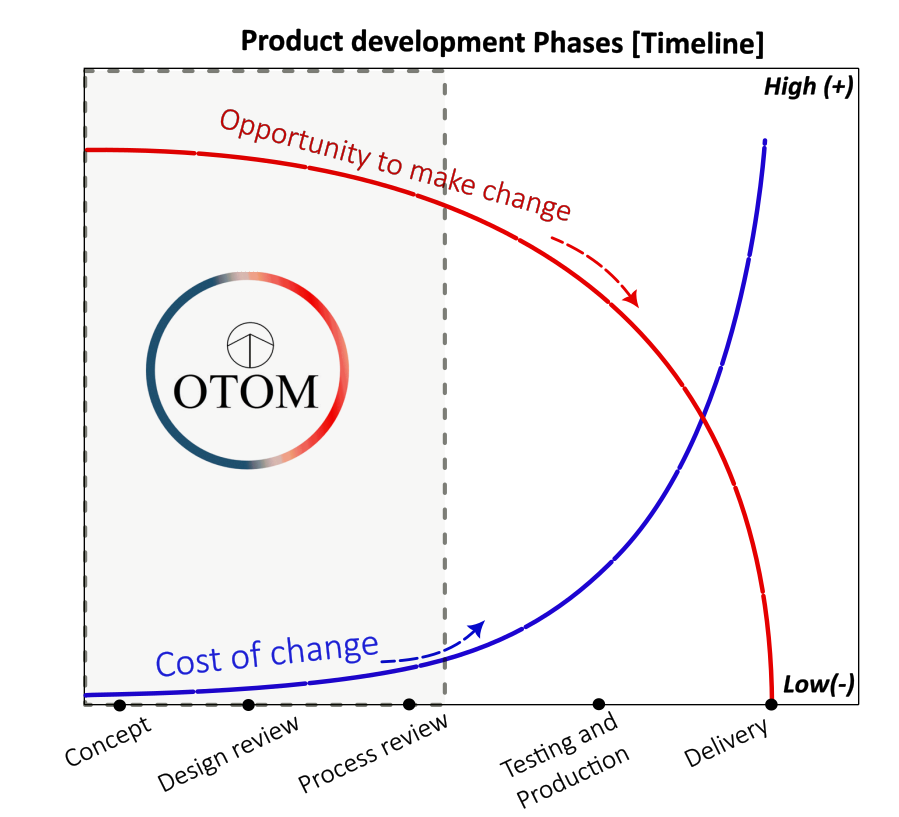

Product development phases and relation with cost and opportunity to make changes:

The value OTOMcomposite provides to customers lies in the ability to implement changes during the initial phases of development, ensuring greater flexibility and optimization.

OTOMcomposite offer:

•Software license

•Engineering service (perform simulation and optimization)

•Onsite Metrology (collecting information for simulation case)

•Consultancy for the case study and design decision

Featured Article:

CompositesWorld | Gardner Web