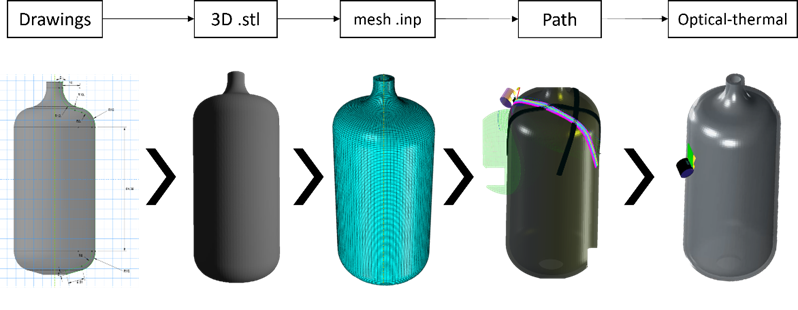

The replacement of metallic reinforcement layers in the multilayer structure with thermoplastic FRP offers a viable solution to address sustainability concerns. Enhancing the longevity of a LATW/LATP product necessitates improved production quality, particularly in terms of bond strength achieved through precise control of the nip-point temperature. To mitigate the costs associated with trial and error, the implementation of a simulation tool becomes indispensable. This can only be achieved by employing a physics-based model, representing a sustainable development in the production cycle aimed at regulating this process. The comprehensive automation procedure serves as the ultimate output solution derived from the LATW/LATP simulation model, propelling LATW/LATP production to the forefront of sustainability. As a result, this approach minimizes waste and enhances the overall quality of the final product, thereby benefiting society, the economy, and natural resources. It fosters a harmonious relationship with nature and contributes to a prosperous existence.

Thank you for reading this post, don't forget to subscribe!Be Part Of New Products sustainibility

Industry 4.0 and sustainability