The implemented algorithms were developed based on mathematics including analytical and numerical methods together with the experimental observation of thermoplastic and composite products to improve the production quality of FRP products. Such a fast model suitable for in-line monitoring by integrating all steps in the LATW/LATP process for prediction and control of bonding quality is not available. However, OTOM makes everything easier, faster, and more reliable for a good bonding quality. In addition, no such software on the market is available to model this process for inline process control.

Thank you for reading this post, don't forget to subscribe!

Benefits:

•Simulation to predict and manage to process

•Improve process quality and accuracy

•Providing guidelines for manufacturing decisions

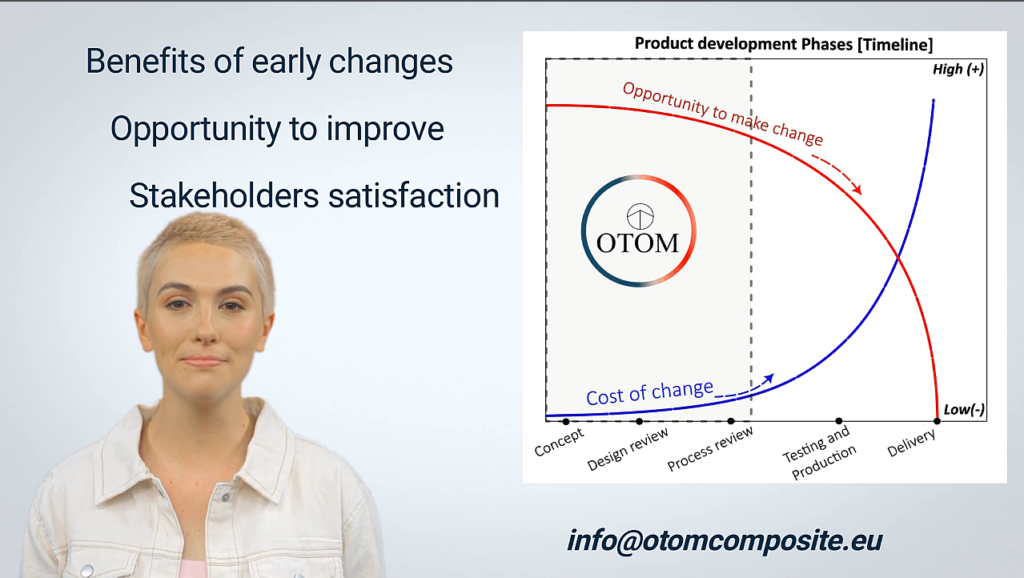

•Help to improve process setup in the early stages

•More streamlined and intelligent process

•Shorten trial-and-error loops

•Enable fast training of manufacturing personnel

•Digitization for composites 4.0 •One-shot process

•Quick identify the best process parameters

•Remove\reduce destructive and non-destructive tests (NDT)

•Cut raw material costs by up to 50%

•Reduces weight, waste, tooling, and labor cost

•Reduced lead times and environmental footprint