The latest product list available to a customer for the AFP process of composite products is below:

Thank you for reading this post, don't forget to subscribe!

Process simulation and optimization service

- Are you manufacturing a composite part with automated fiber placement (AFP) technology?

- Are the AFP process settings and product optimized?

- Are you planning to reduce expensive tests and trials?

- Do you plan to improve the throughput time of your design and process?

Your tailored composite automated fiber placement can be optimized. Our physics-based software, OTOM AFP V.1.22, can help you to know the process temperatures beyond the visible point of the thermal camera. We help you to resolve:

- Temperature localization

- Process deviations

- Reliability issue

- Insufficient bonding quality

- Non-homogeneous quality

- High engineering lead time

- High final cost

OTOM AFP V.1.22

OTOM or Optimizing Thermo Optical Modeling is a physics-based CAE Software for automated fiber placement process. OTOMcomposite software can select and control accurately hundreds of AFP process parameters to control the process to have a robust and ideal tailored product. OTOM is not only the simulation software for AFP but also a tool to interact with the PLC to increase your productivity.

Commercial companies and research centers could request a free trial license to see how it may benefit them.

| Item option | Details |

|---|---|

| Basic functions | Optical-thermal Steady-state analytical geometry (Cylinder, domes, flat panel) Laser distribution manager, Laser divergence, Roller deformation, Placement/Winding on Tape/Sub Optimization Placement/Winding Angle, Velocity, Laser power, and intensity, Laser head size, location, and orientation Post-processing Internal OTOM AFP plots, Rendering and smoothing plots, Tecplot output |

| Advanced | Non-linear thermal properties Temperature-dependent heat capacitance, density, heat conductance Transient thermal analysis Time-dependent thermal simulation, Variable laser power, velocity, Variable material properties, Continuous manufacturing type, Tecplot animations, OTOM AFP animations BRDF Ray-tracing reflections Fiber orientation reflection pattern PLC ADS communication module Connection with TwinCAT XAE |

| Kinematic determination on cylinder/domes: Path definitions, Multiple Laser modules, Laser Tilt/ Yaw variation Kinematic determination on CAD: Path definitions, Multiple Laser modules, Laser Tilt/ Yaw variation, Tape-Rack blade Optical analysis on cylinder/domes: Ray-tracing geometry dependent Optical analysis on CAD: Ray-tracing geometry dependent, Post-process optical analysis: Ray-tracing output presentation, Heat intensity on Tape/sub [Cuda] | |

| GPU Accelerator | Cuda computing Boost for UOT-CAD analysis |

| CAD based AFP simulation | Thermal UOT Analytic geometry Temperature variation curved surfaces, Thermal UOT CAD Temperature variation, CAD models, Layer on layer thermal placement |

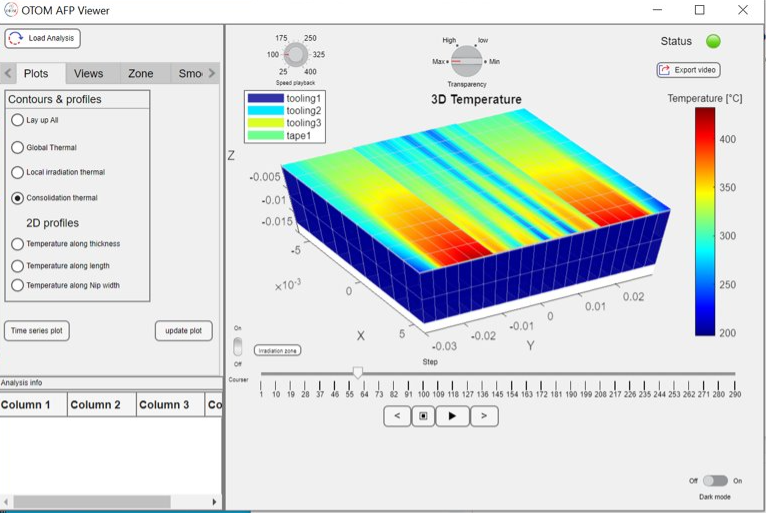

OTOM AFP Viewer

OTOM AFP viewer software is a dedicated post-processing tool to analyze results from the OTOMcomposite automated fiber placement (AFP) software.

This software is provided Free of cost to OTOM Engineering service customers.

- Load different thermal analysis outputs

- View figures data and animation at every step

- See-through thickness information

- Show/hide different layers

- Extract Temporal (time-series) plots of the heated zone

- Extract Temporal (time-series) plots of the specific location

- Global and local temperatures.

- Global Lay-up at every step

- Different representation styles and views

- Generate animation video and pictures

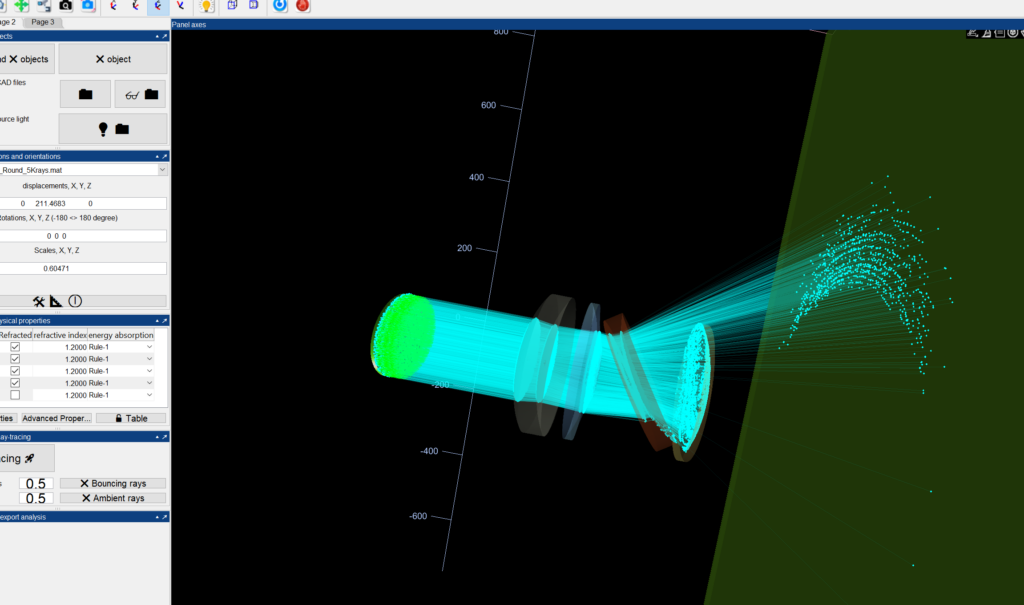

OTOM Ray-tracer

- Versatile Analysis:

- Conduct high-fidelity ray tracing on both opaque and transparent objects.

- Add multiple objects for optical characterization and analyze light interactions with various surfaces.

- Microscopy Integration:

- Import microscopy data for enhanced surface characterization.

- Incorporate surface roughness details for a higher level of precision.

- Precision Engineering:

- Tailor interventions based on real-world microscopic data.

- Optimize surface engineering projects with unparalleled precision.