Hydrogen tanks in the automotive industry, Fuselage of airplanes, or high-resistance tubes in the oil and gas industry are some of the applications of FRP (Fiber Reinforced Plastic) products that can be made by the AFP/LATW/LATP process. Thanks to these advanced techniques, a seamless production chain of FRP products is possible.

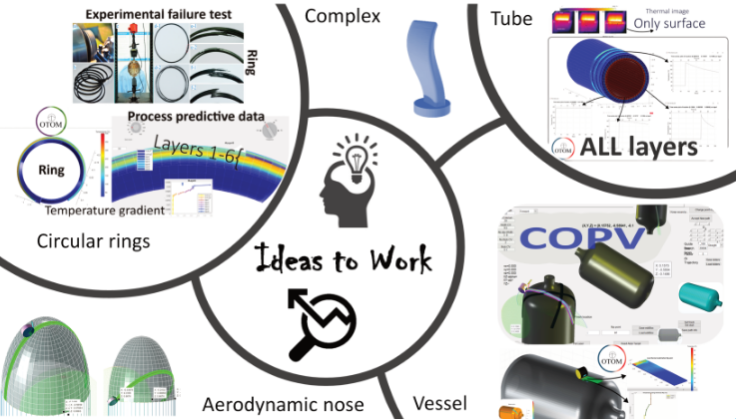

Thank you for reading this post, don't forget to subscribe!However, optimized quality and defect-free design are a challenge. A predictive simulation ensures proper process design and quality among the fiber-reinforced layers to ensure bonding strength during the Winding/Placement process. For that reason, an integrated computer-implemented method like OTOM is necessary. Analyzing kinematic-dependent thermal history, laser irradiation, absorption, and reflection during placement on the mandrel is our approach to making inferior FRP products.

>> We help our customers to make it easier and cheaper.